Hello all! Making lots of good progress and several lessons learned on this first product design. Biggest lesson is that I should have started hiring and working with contract designers earlier on. What I thought were simple tasks like boiler cap and steam valve designs turned out to be rather significant parts and complex systems.

Espresso Machine Assembly Technician job is posted on the site. We’ve received 18 applications with several excellent candidates. The next week or two will be spent interviewing, hiring, and onboarding.

Hardware

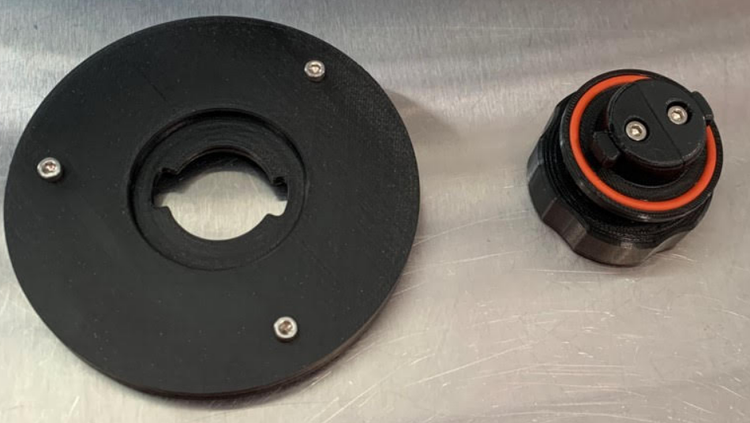

Good news is that the boiler cap design is just about complete! We did a few iterations of quick 3D printed prototypes to dial in the design and user experience. The design is nice in that it sports an off the shelf o-ring for sealing, integrated vacuum breaker valve (similar to the piston valve design), and has a small “locking” detent to make it difficult to remove when under pressure. Metallic prototypes are being made now to complete the testing but I’m confident enough in the design to move forward.

The last significant part being worked on is the steam valve interface which has challenging packaging constraints to keep within the small footprint.

You can check out the updated checklist here.

Version 2 of the boiler cap design 3D printed to test o-ring squeeze and locking pocket. Final cap design still maintains the integrated boiler pressure gauge.

Software

Acaia scale integration resolved and all scales tested and working with the app.

Sincerely,

Ross Ainsworth